10 FAQ About Bandsaws Answered

Do you want to know how bandsaws work but don’t know where to begin? Say no more! Below, we answer 10 of the most frequently asked questions about bandsaws. Whether you’re a beginner looking to buy your first machine or an experienced woodworker wanting to refine your skills, this guide will provide helpful insights on everything from choosing the right blade to mastering precise cuts. Let’s dive into the essentials!

What is a bandsaw used for?

A bandsaw is a power saw that uses a continuous, sharp blade of toothed metal stretched between two or more wheels to cut through materials. Bandsaws can cut various materials, but their main applications are metalworking, lumbering, and woodworking.

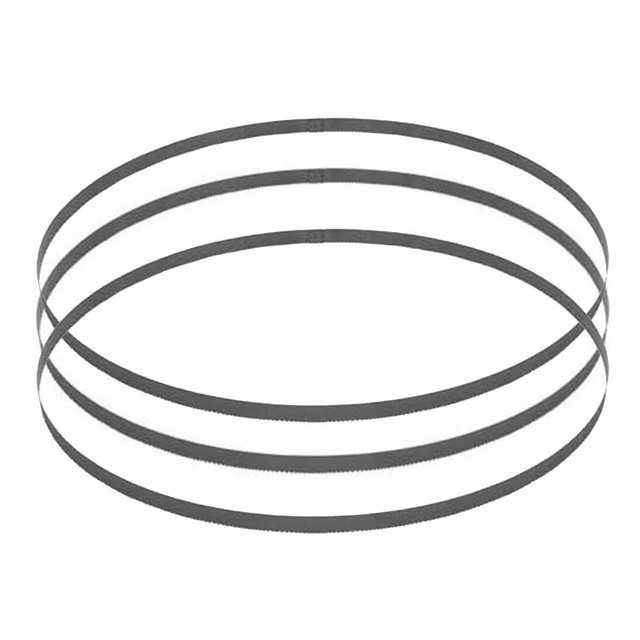

How do I choose the right bandsaw blade?

The wheel size on your saw usually determines the blade’s length, thickness, and width. Smaller bandsaws require thinner blades to prevent the welds from breaking.

While fewer teeth per inch (coarse pitch) will cut faster but rougher, more teeth per inch (fine pitch) will cut slower but smoother. Generally speaking, select blades that will always have three or more teeth embedded in the material. For tougher woods, use blades with finer pitches; for softer woods, use blades with coarser pitches.

Coarse Pitch Bandsaw Blades

As mentioned above, a coarse pitch bandsaw blade usually has 3 to 6 teeth per inch (TPI). Because of its shape, it is perfect for cutting thicker or softer materials like wood, plastics, or non-ferrous metals. The greater gaps between the teeth aid in removing larger chips and keep the blade from clogging while making cuts.

Fine Pitch Bandsaw Blades

A fine-pitch bandsaw blade has more teeth per inch (TPI), typically 14 to 24. This blade is made for thinner or harder materials, such as metal, hardwood, or intricate woodworking tasks, to enable smoother, more accurate cuts. Compared to coarse-pitch blades, the closely spaced teeth give better control and produce finer sawdust, but they also cut more slowly.

When to change bandsaw tyres?

You should change your bandsaw tyres when they become worn, cracked, or loose, as these conditions can affect blade tracking and cutting accuracy. Signs that it’s time to replace them include visible damage, frequent blade slippage, or uneven blade wear. Regularly inspecting the tyres for wear and replacing them as needed helps ensure smooth operation and extends the life of your bandsaw blades.

How do I maintain my bandsaw?

Maintaining your bandsaw involves regular cleaning, blade inspection, and lubrication. Here are some tips for prolonging the life and smooth operation of your bandsaw.

- Clean the wheels, blade guides, and table to keep the machine free of sawdust and debris.

- Regularly check the blade for dullness, cracks, or uneven wear and replace it when necessary.

- Lubricate moving parts like the tensioning mechanism and bearings to prevent wear.

- Finally, ensure proper blade tension and alignment to maintain cutting accuracy and prolong the life of the bandsaw.

Can bandsaws cut metal?

Yes, bandsaws can cut metal, but you’ll need a specific metal-cutting bandsaw or the right blade for the job. Metal-cutting blades usually have a finer tooth pitch (higher TPI) to handle the tougher material and achieve smoother cuts. Slower blade speeds and, occasionally, lubrication are also necessary to avoid overheating and blade wear when cutting metal.

What safety precautions should I take when using a bandsaw?

Here are a few tips on how to stay safe while using your bandsaw:

- Always use safety goggles and hearing protection when using a bandsaw.

- Don’t wear loose clothing and jewellery that could catch.

- Never force material through the saw; use push sticks or guides to keep your hands away from the blade.

- Ensure the blade guard is securely fastened and adjusted, and the blade is sharp and tensioned appropriately.

- Before making any adjustments or cleaning, always turn off the saw and wait for the blade to halt.

How do I adjust the blade tension on a bandsaw?

The blade tension of a bandsaw can be modified using the tensioning knob or lever, which is normally located on top of the saw. Turn it clockwise to raise tension or anticlockwise to reduce it.

Many bandsaws include a tension gauge that allows you to set the appropriate tension based on the blade width. Proper tension should let the blade remain straight when cutting without excessive wobbling, but it should still bend slightly when gently pressed from the side. Always consult your bandsaw’s handbook for detailed instructions.

What are some common problems with bandsaws, and how can I fix them?

We compiled a list of some of the most common issues with bandsaws and how to fix them.

- Blade drift: Adjust blade tracking and align the blade with the fence.

- Uneven cuts: Check for a dull blade or improper tension; replace or adjust the blade as needed.

- Excessive noise: Tighten screws and inspect bearings for wear; replace worn parts if necessary.

- Blade slippage: Ensure proper tension and replace worn or cracked bandsaw tyres.

- Vibration: Check for loose parts and ensure the machine is placed on a stable surface.

- Slow cutting: This can indicate a dull blade or incorrect blade choice; switch to a sharper or more appropriate blade for the material.

What features should I look for in a bandsaw?

- Robust motor: Ensures adequate power for various cutting tasks.

- Adjustable blade speed: Provides versatility for different materials.

- Reliable blade tensioning system: Maintains consistent performance.

- Sturdy table: Offers adjustable height and tilt for enhanced cutting accuracy.

- Good blade tracking and alignment: Helps maintain precision during cuts.

- Dust collection ports: Facilitates easier cleanup and improves visibility.

- Safety guards: Provide protection while operating.

- Fence or mitre gauge: Aids in making straight cuts and angles.

How often should I replace my bandsaw blade?

Replace your bandsaw blade when it shows signs of dullness, such as increased cutting resistance, burn markings on the material, or a rough finish. Examine the blade after each major job or once a week if it is used often.

If you find fractures, missing teeth, or other damage, it’s time to replace the blade. Regular maintenance and timely replacements will contribute to optimal performance and safety.

Toolden’s Best Selling Cordless Bandsaws

If you have any additional queries, please do not hesitate to contact us at 01358 726719 or by email at

admin@toolden.co.uk