A Comprehensive Diamond Blade Guide: Top 5 N-Durance Diamond Blades

Diamonds have long been admired for their beauty and strength, but did you know they can also serve as cutting tools? Enter the world of diamond blades—a cutting-edge solution that has revolutionized the construction and manufacturing industries. In this blog post, we’ll delve into the intricacies of diamond blades, exploring what they are, how they’re made, their key features, compatible power machines, and the materials they can cut.

What is a Diamond Blade?

A diamond blade is a cutting accessory designed for precision and efficiency. Unlike conventional blades that rely on sharp edges, diamond blades employ diamond particles, the hardest naturally occurring material, to cut through a wide range of tough and abrasive materials. The incorporation of diamonds into the blade’s edge enhances its cutting prowess and prolongs its lifespan.

How Are Diamond Blades Made?

The manufacturing process of diamond blades is a blend of advanced technology and skilled craftsmanship. It involves the following steps:

- Powder Mix Preparation: A mixture of synthetic diamond particles and metal powders, often cobalt, is created. The diamond particles act as the cutting agent, while the metal powders serve as a bonding material.

- Mixing and Compacting: The diamond and metal powder mixture is carefully blended and subjected to high pressure to form a compacted blade segment.

- Sintering: The compacted segments are then sintered at high temperatures and pressures. The metal powders fuse during this process, creating a strong bond that securely holds the diamond particles in place.

- Segment Attachment: The sintered segments are attached to the blade’s core through brazing or laser welding, creating a sturdy and functional diamond blade.

Main Features of a Diamond Blade

- Diamond Grit: The diamond grit size determines the blade’s cutting efficiency. Smaller grit sizes are ideal for harder materials, while larger ones work better on softer materials.

- Segment Design: The blade’s segment design can vary, such as continuous rim, segmented rim, turbo rim, and more, each tailored for specific cutting applications.

- Core Material: The blade’s core can be made from various materials, such as steel, aluminium, or composite materials, each offering different levels of durability and stability.

- Cooling Holes: Some diamond blades have cooling holes to dissipate heat, reducing the risk of blade deformation and prolonging their life.

Power Machines Compatible with Diamond Blades

Diamond blades are versatile tools suitable for various power machines, including:

- Angle Grinders: Used for small-scale cutting tasks and precise shaping.

- Circular Saws: Ideal for straight cuts in larger materials.

- Tile Saws: Designed specifically for cutting tiles and ceramics.

- Concrete Saws: Engineered to cut through tough materials like concrete and asphalt.

Materials that Can Be Cut with a Diamond Blade

Diamond blades are renowned for their ability to cut through a wide array of materials, such as:

- Concrete and Asphalt: Used in construction projects for roadways, sidewalks, and buildings.

- Natural Stone: Suitable for cutting granite, marble, and other ornamental stones.

- Ceramic Tiles: Precise cutting for tiling and interior designs.

- Glass: Specialized blades are employed for clean and accurate glass cutting.

- Metal: Diamond blades can also cut metals with the appropriate configuration.

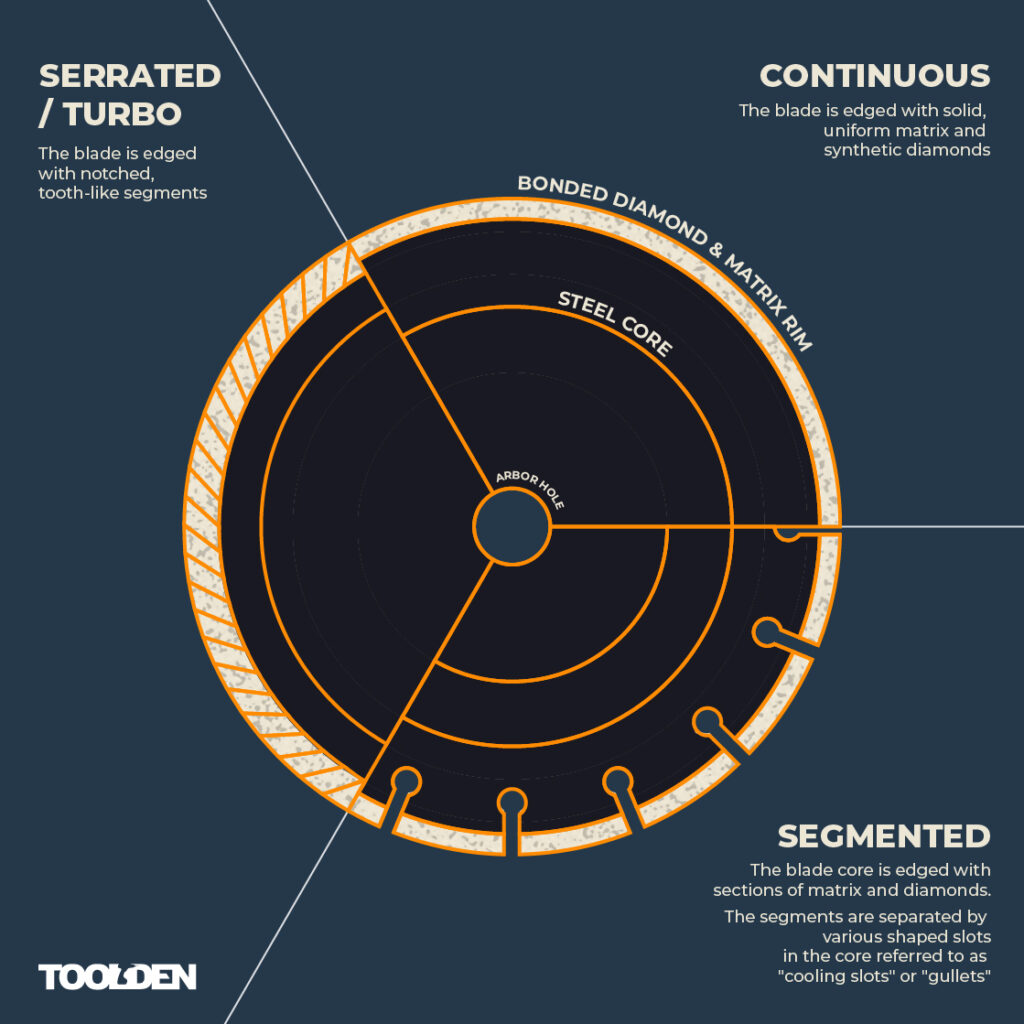

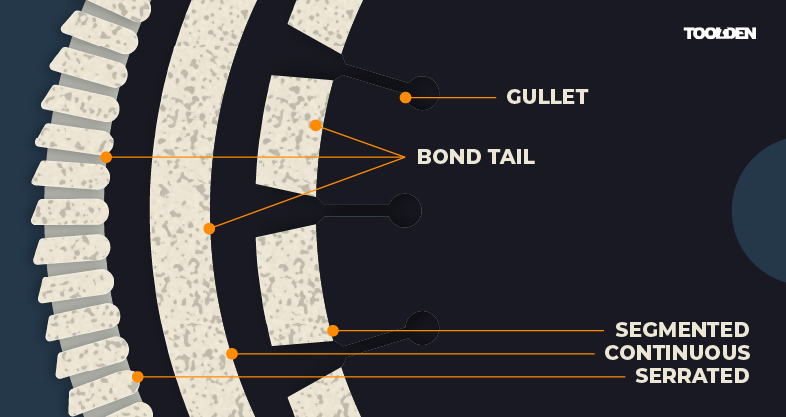

Types of Diamond Blades Depending on the Blade Segment

The segment is the part of the blade that actually does the cutting. As stated above, the blade segment is made when the diamond and metal powder mixture are blended and subjected to high pressure. Three types of segments are used in diamond blades: continuous smooth rim, serrated/turno rim and segmented rim.

Continuous Smooth Rim

Diamond blades with a continuous smooth rim make clean, smooth cuts on glazed ceramic tile, marble, granite, porcelain, and quarry tile. They are available with wet and dry specifications and diameters ranging from 4″ to 14″.

Serrated/Turbo Rim

Diamond blades with serrated or turbo rims can quickly and with little chipping cut through Roof tile, unglazed tile, masonry, brick, block, paver, stone, and concrete. They are designed for dry use but can also be used with water. They range in diameter from 4″ to 16″.

Segmented Rim

Segmented rim diamond blades offer maximum cutting strength and life in concrete, reinforced concrete, asphalt, masonry, brick, block, paver, and stone. They are available in wet and dry specifications and have diameters ranging from 4″ to 60″.

Types of Diamond Blades Depending on the Type of Cutting

Dry Cutting

The dry-cutting diamond blade is particularly appealing because of the rising popularity of portable saws and diamond blades’ adaptability to effectively handle most ceramic, brick, stone, and concrete materials.

Dry cutting blades are also used where water is not permitted or handy or when the amount of cutting required is so small that setting up water-cooled equipment would be inefficient. The saw operator does not have to worry about freezing water in cold conditions.

Wet Cutting

Most contractors would rather use wet-cutting diamond blades whenever possible. The water used to cool the steel core increases the blade’s longevity, improves the cutting process, and improves safety by lowering the dust signature. Applications include pottery, brick, stone, and concrete.

NOTE: Dry cutting blades can be used with water; however, wet cutting blades can never be used dry.

Top 5 Best-Selling N-Durance Diamond Blades

N-Durance DC332 General Purpose Segmented Diamond Blade 230 x 22.2mm

The N-Durance General Purpose Segmented Diamond Blade, 230 x 22.2mm, is a versatile cutting tool commonly used in construction and fabrication projects. Its segmented design features diamond-embedded edges that provide efficient cutting performance across various materials, including concrete, brick, stone, and masonry. The 22.2mm bore size makes it compatible with various angle grinders and cut-off machines. This blade is renowned for its durability and ability to handle both dry and wet cutting conditions, making it a reliable choice for professionals in construction and related industries.

DC332 Features

- Suitable for cutting most building materials

- N-durance’s longest-life diamond blade range

- Aggressive cut

- Turbo segment for a smooth & precise cut

- The ideal combination of speed and life

- Massive 10mm segment for extended blade life

- Hardened core for increased durability

- Semi-transparent for improved visibility

DC332 Specification

- Blade Diameter: 230mm

- Bore Size: 22.2mm

- Rim: Segmented

N-Durance M5JET230 5-in-1 Multi-Purpose Diamond Blade 230 x 22.2mm

The N-Durance 5-in-1 Multi-Purpose Diamond Blade, measuring 230 x 22.2mm, is a versatile cutting tool designed for various construction and renovation tasks. Its innovative 5-in-1 design combines different segments optimized for cutting materials such as concrete, brick, tile, metal, and wood. Its 22.2mm bore size is compatible with a range of angle grinders and cut-off machines. This blade’s adaptability and durable diamond-embedded edges make it a valuable choice for professionals seeking efficiency and convenience across a spectrum of cutting applications.

M5JET230 Features

- 5 in 1 Material Blade

- Premium Diamond Quality

- Strengthened Core

- Maximum Product Life

- Angled Segment

- Cooling Technology

M5JET230 Specification

- Blade diameter: 230mm

- Disc bore size: 22.2mm

- Wet/Dry Cutting

N-Durance M5JET350 5-in-1 Multi-Purpose Diamond Blade 350 x 25mm

The N-Durance 5-in-1 Multi-Purpose Diamond Blade sized 350 x 25mm, is a versatile cutting tool for various construction and renovation tasks. Its unique 5-in-1 design combines different segments optimized for cutting materials such as concrete, brick, tile, metal, and wood. Its 25mm bore size is compatible with larger angle grinders and cut-off machines. This blade’s adaptability and durable diamond-embedded edges make it an excellent choice for professionals seeking efficiency and convenience across a wide array of cutting applications in large-scale projects.

M5JET350 Features

- 5 in 1 Material Blade

- Premium Diamond Quality

- Strengthened Core

- Maximum Product Life

- Angled Segment

- Cooling Technology

M5JET350 Specification

- Blade diameter: 350mm

- Disc bore size: 25mm

- Wet/Dry Cutting

N-Durance M5JET300 5-in-1 Multi-Purpose Diamond Blade 300 x 20mm

The N-Durance M5JET300 5-in-1 Multi-Purpose Diamond Blade sized 300 x 20mm, is a versatile cutting tool designed to excel in various construction and renovation tasks. Its innovative 5-in-1 design combines specialized segments for cutting materials such as concrete, brick, tile, metal, and wood. With a 20mm bore size, it’s suitable for various angle grinders and cut-off machines. This blade’s adaptability, coupled with its robust diamond-embedded edges, makes it a reliable choice for professionals seeking efficiency and flexibility across diverse cutting applications in smaller and larger projects.

M5JET300 Features

- 5 in 1 Material Blade

- Premium Diamond Quality

- Strengthened Core

- Maximum Product Life

- Angled Segment

- Cooling Technology

M5JET300 Specification

- Blade diameter: 300mm

- Disc bore size: 20mm

- Wet/Dry Cutting

N-Durance DC004 Mortar Raking Blade 115mm x 6.4mm

The N-Durance Mortar Raking Blade, measuring 115mm x 6.4mm, is a specialized cutting tool designed for removing mortar from joints in masonry and brickwork. Its slim profile allows for precise and controlled mortar removal without damaging surrounding materials. Its 6.4mm thickness makes it suitable for use with angle grinders. This blade’s design and dimensions make it an ideal choice for professionals in tuckpointing and restoration projects, enabling efficient and accurate mortar removal while maintaining the integrity of the surrounding structure.

M5JET300B Features

- Compatible with all major brands of 115mm and 125mm angle grinders.

- Suitable for all kinds of masonry dry cutting.

M5JET300B Specification

- Blade diameter: 115mm

- Disc bore size: 6.4mm

- Dry Cutting

In conclusion, diamond blades have elevated the cutting industry to new heights, offering unparalleled precision and durability. Their unique construction, coupled with diamonds’ remarkable properties, has led to a versatile tool that can slice through some of the toughest materials. Whether a DIY enthusiast or a professional contractor, diamond blades are an indispensable asset in your toolkit, bringing efficiency and excellence to your cutting endeavours.

FAQs

Can I cut multiple materials with one diamond blade?

Diamond blades are engineered with specific materials in mind due to different substances’ varying hardness and properties. While some general-purpose diamond blades can handle multiple materials, it’s recommended to use specialized blades for the best results. Using the appropriate blade ensures cleaner cuts, longer blade life, and improved safety.

Can I use the same diamond blade for different power tools?

While diamond blades are versatile, using the right blade for the right tool is essential. Power tools have varying RPMs (rotations per minute) and cutting mechanisms. Using a blade not designed for a specific tool can lead to reduced performance, overheating, and even safety hazards. Always select a blade that’s recommended for the tool you’re using.

How do I choose the right diamond blade for my project?

Choosing the right diamond blade involves considering the material you’ll be cutting and the power tool you use. Blade specifications, such as diameter, arbour size, and cutting depth, should match the tool’s capabilities. Additionally, different blades are designed for specific materials like concrete, stone, tile, or metal. Select a blade specifically designed for your project’s material and your tool’s specifications.

Need help deciding which to choose? Need some help with your order? Our new help centre has a wide range of helpful articles and guides!

If you have any additional queries, please do not hesitate to contact us at 01358 726719 or by email at admin@toolden.co.uk